P7) 416 OFPPk (Cell Fusing)

CELL FUSING

Individual Cell fusing can be easy and can go very complex. To fused a single or a number of cells is not a issue. Off-the shelf product is more than enough. To fused a few hundred of cell will need a different approach.

In order to implement it on the 416 pack, have done some research and look for readily made product. eg: SMT fuse, Glass fuse, Flat fuse.... all sort of fuses that come close to what I intend to use. Electrically it may be alright, physical dimension doesn't really match and required some amendment to the existing design. No practical and the cost really adds up.

In search of solution, while gathering some information in the community, I realize that the fuse rating can be higher than the cell discharge or charge rating.. It is to prevent overly charge or discharge situation. If the fuse rating is very close or exact to the maximum value. It may blow too easily and cause undesirable loading on the BMS. Moreover, all the powerwall packs will be monitored thru a proper BMS which have a better control over the pack.

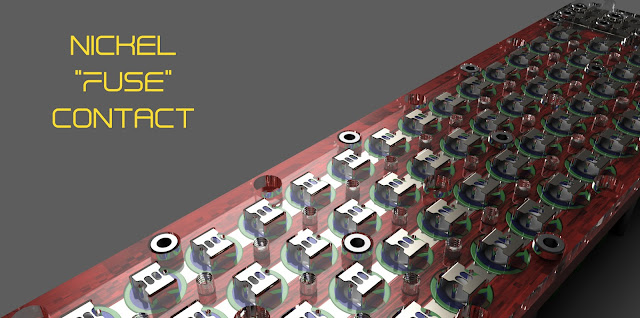

With this, I created a few designs around on the current nickel strip and finally come out with this simple idea. There'll be three very thin trace on the nickel plate to add as a fuse... The slim cut will be enough for normal operation...

This nickel contact "Fuse" will be custom made to the specific thin trace. As such, it need to be very exact in dimension.

Each thin trace can withstand in excess of 8A. The thin trace can be cut to suit each users needs for failsafe operation or leave it as it is for high powered operation.

All cells will have a nickel "Fuse" installed on the positive end. This can be swap to the negative side if needed. All nickel "Fuse" is facing on the exterior, as such it is easy to identify if there's any fault.

Comments